Bulk Tank Inc. has developed a system for using bulk dry drilling fluid additives in place of traditional sack material. This system eliminates all problems normally associated with sack chemicals usage. SYSTEM: The dry chemical dispensing system is composed of the following components. 1. BULK TRANSPORT CONTAINERS: 70 cubic ft. bulk containers constructed of polyurethane, stainless steel or carbon steel are used to transport and to store all drilling fluid chemicals. The dimensions ofthe tanks are 48" w X 56" l X 80" h. All containers have lifting slings and forklift channels standard. The discharge is 10" in diameter. 2. WEIGH SKIDS: The bulk containers sit on the weigh skids. The weigh skids can be used separately or they can be manifold for multiple dispensing applications. When the container is placed onweigh skid a specially designed fitting compresses to form a air tight seal. This seal assures that no chemical is spilled or creates dust. Using load cells and an accuated valve all chemical additions are controlled from the weigh skid. The dimensions of the weigh skids are 50" width X 65" length X 21" height.

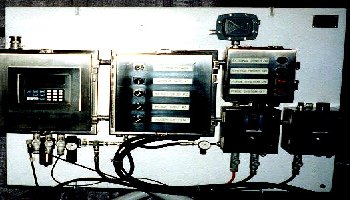

3. TRANSPORT SYSTEM: A 2 7/8" flexible spiral auger is used to transport the dry chemical from the weigh skid to the mud hopper.The auger is completely enclosed inside either 3" PVC or carbon steel pipe. Being that the transport system is completely enclosed and without air injected dust from the dry chemical is negligible. Since there are no corners, gears, or pins to cause friction the transport system is virtually maintenance free. The transport auger system is powered by a 1 HP explosion proof 3 phase electric motor. The chemical is moved at a rate of 150 cubic ft. an hour. 4. CONTROLLER: A specially designed process weigh indicator (PWI) controls the entire operation of the system. The PWI uses loss in weight signals from the weigh skid to accurately dispense chemical into the transport line. A specifically designed software program makes chemical addition easy. Additions are made on a time bases. The PWI uses 120v AC for power.

5. INSTALLATION: The installation of the system is very easy, and generally takes about 24 hours. In most instances no modification to the drilling rig is required. The weigh skids are bolted together and braced. The auger transport line is braced every 10 feet. The electric motor is mounted and braced by the mud hopper with a discharge placed over the hopper. The PWI is placed at a convenient location for operation. All electrical lines are terminated from the drilling rig. The system is so flexible and has such a small footprint that it can be easily rigged up on any rig in the world.

|